Technology and stories of hope in breast cancer

The event highlighted Sense Glove, an innovative technology co-financed by COMPETE 2030, dedicated to breast cancer prevention.

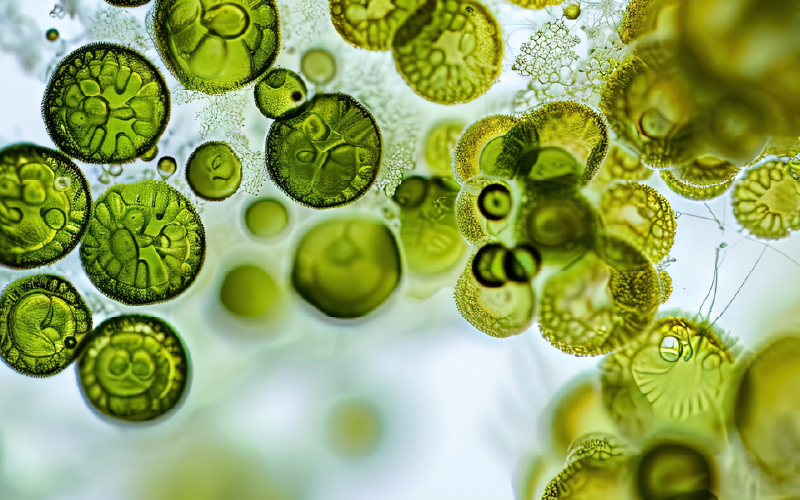

This operation stands out for its production of microalgae and the use of the resulting biomass to create sustainable products for the sector.

AQUA4ALL revolutionises aquaculture through bioremediation

The AQUA4ALL operation, co-financed by COMPETE 2030, innovates in the field of aquaculture with the bioremediation of RAS effluents. This project stands out for the production of microalgae and the use of the resulting biomass to create sustainable products for the sector.

Objectives of the Operation

The main objective of AQUA4ALL is to develop an ecosystem service that enables the effective bioremediation of effluents from recirculating aquaculture systems (RAS). To this end, the operation uses advanced microalgae production technologies. With the biomass produced, the operation will develop two new products: a sterilised product for the cultivation of live food and marine fish larvae, called CleanAlgae, and a water conditioner with bactericidal and bacteriostatic properties, called AquaDefense.

“This project represents an important milestone for sustainability in aquaculture. We are committed to promoting more environmentally friendly practices,” says Carolina Castro, R&D Manager at FLATLANTIC. She adds: “The growth strategy of FLATLANTIC, Europe’s largest flatfish producer, has driven the company to make significant investments in recirculating aquaculture systems (RAS). This technology allows for high-scale production, greater energy efficiency and a substantial reduction in the use of natural resources. However, environmental sustainability is one of the central pillars of FLATLANTIC’s corporate culture and is present in all its long-term investment plans. It was in this context that AQUA4ALL emerged, a project funded by COMPETE, motivated by the company’s concern to develop strategies to mitigate the environmental impact of RAS effluent resulting from the production of sole and turbot — or even to generate added value from this by-product.

Innovative Nature and Multidisciplinary Approach

The innovative nature of AQUA4ALL lies in the semi-industrial scale implementation of microalgae cultivation technology for bioremediation of RAS system effluent. In addition, the project focuses on creating value-added products for aquaculture from microalgae biomass. This approach involves multidisciplinary collaboration in the fields of biotechnology and aquaculture, applying the consortium’s expertise.

Consortium of Excellence

AQUA4ALL is presented by FLATLANTIC, in consortium with NECTON and the NBERIS, S2AQUA and GREEN CoLabs. This collaboration ensures that the project’s objectives are met. NECTON ensures the use of the technology, while the NBERIS contributes scientific excellence and innovative methodologies.

Environmental Impact and Animal Welfare

In addition to promoting more sustainable practices, the AQUA4ALL operation focuses on controlling pathological aspects. The proposal is to increase animal welfare in aquaculture. ‘Without the initial impetus provided by the COMPETE 2030 Programme, which will provide funding of almost €269,000, it would not be feasible to mobilise a multidisciplinary innovation ecosystem such as the one that has been brought together,’ concludes Carolina Castro. ‘This project will therefore be of enormous importance to FLATLANTIC, as it will enable the continuous improvement of the production process and the establishment of more sustainable and environmentally friendly practices.’

This promising project promises to bring several advantages not only for the environment but also for the aquaculture industry, contributing to a more sustainable future.

04 February 2026